Bronze cabinet pulls

I was provided with 21 silicon bronze drawer and cabinet pulls forged to look like bamboo of two different lengths. I turned 42 standoffs exactly the same length with a tapped hole for mounting hardware. I also plunged an endmill twice into each pull for a flat-bottomed hole the standoffs would be silver soldered into.

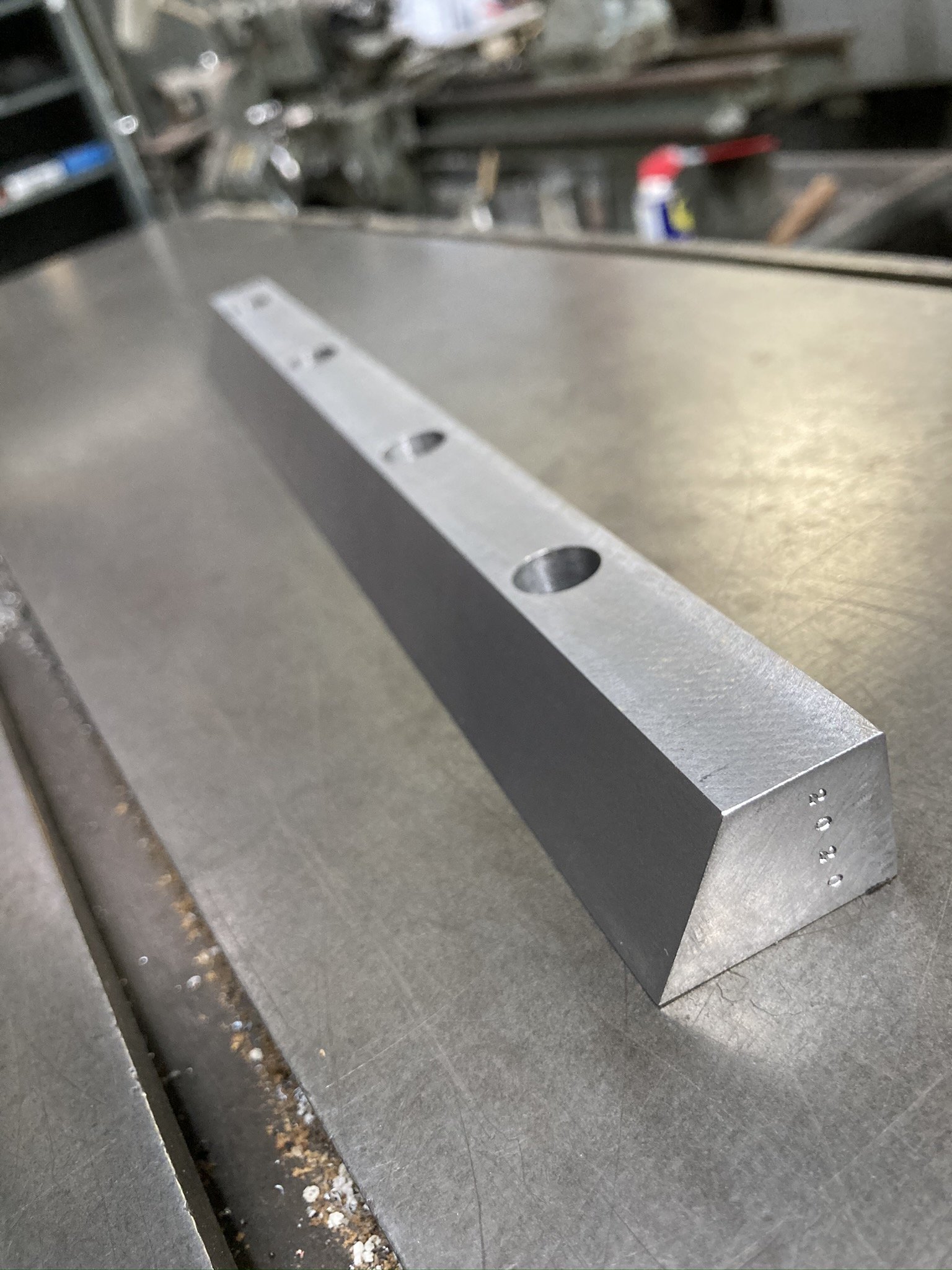

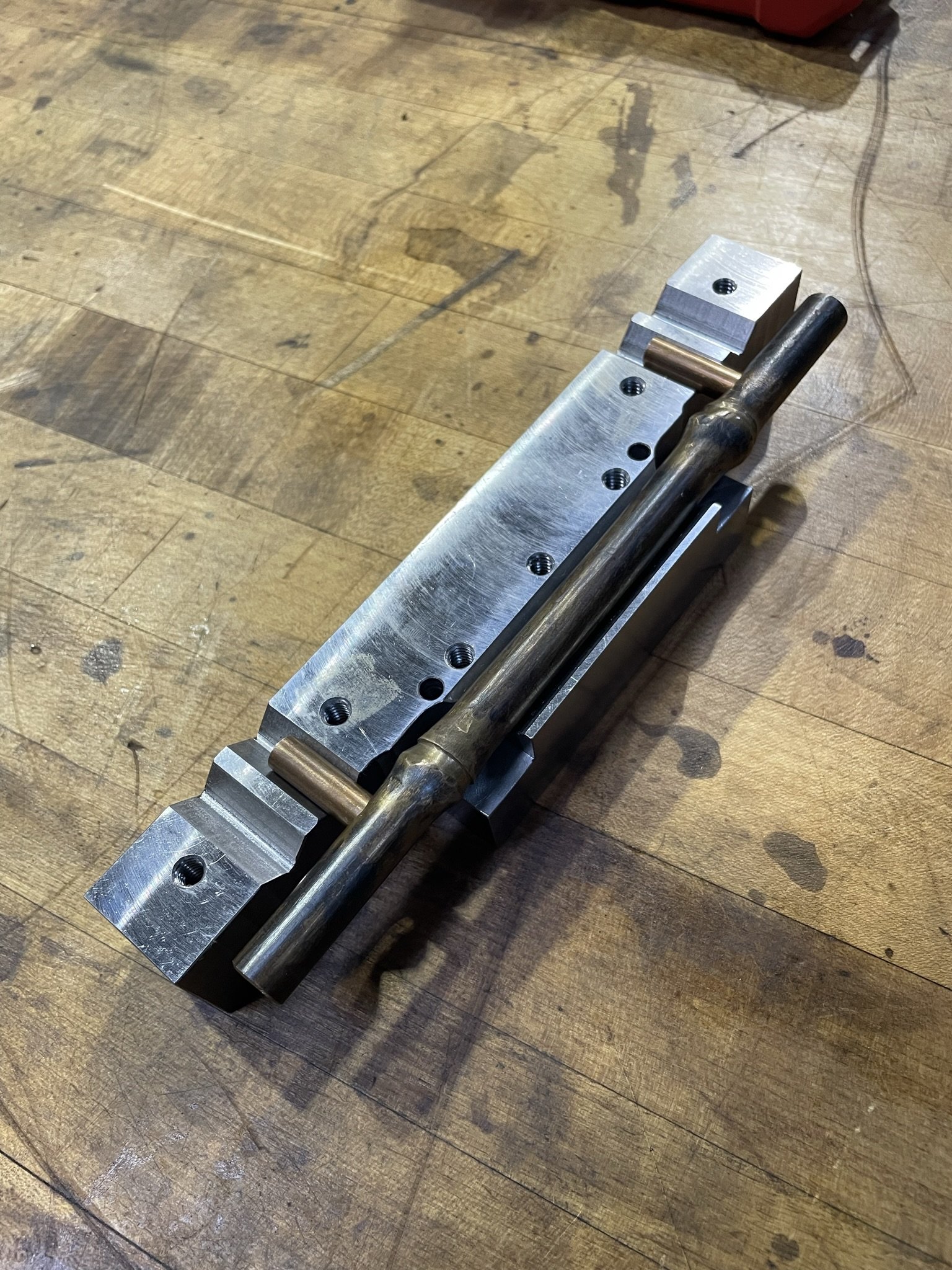

dovetail gib

This part was made to replace a worn-out removable sliding dovetail for the tensioning slide on a large band sawmill. It is ductile cast iron with a smooth finish to reduce friction.

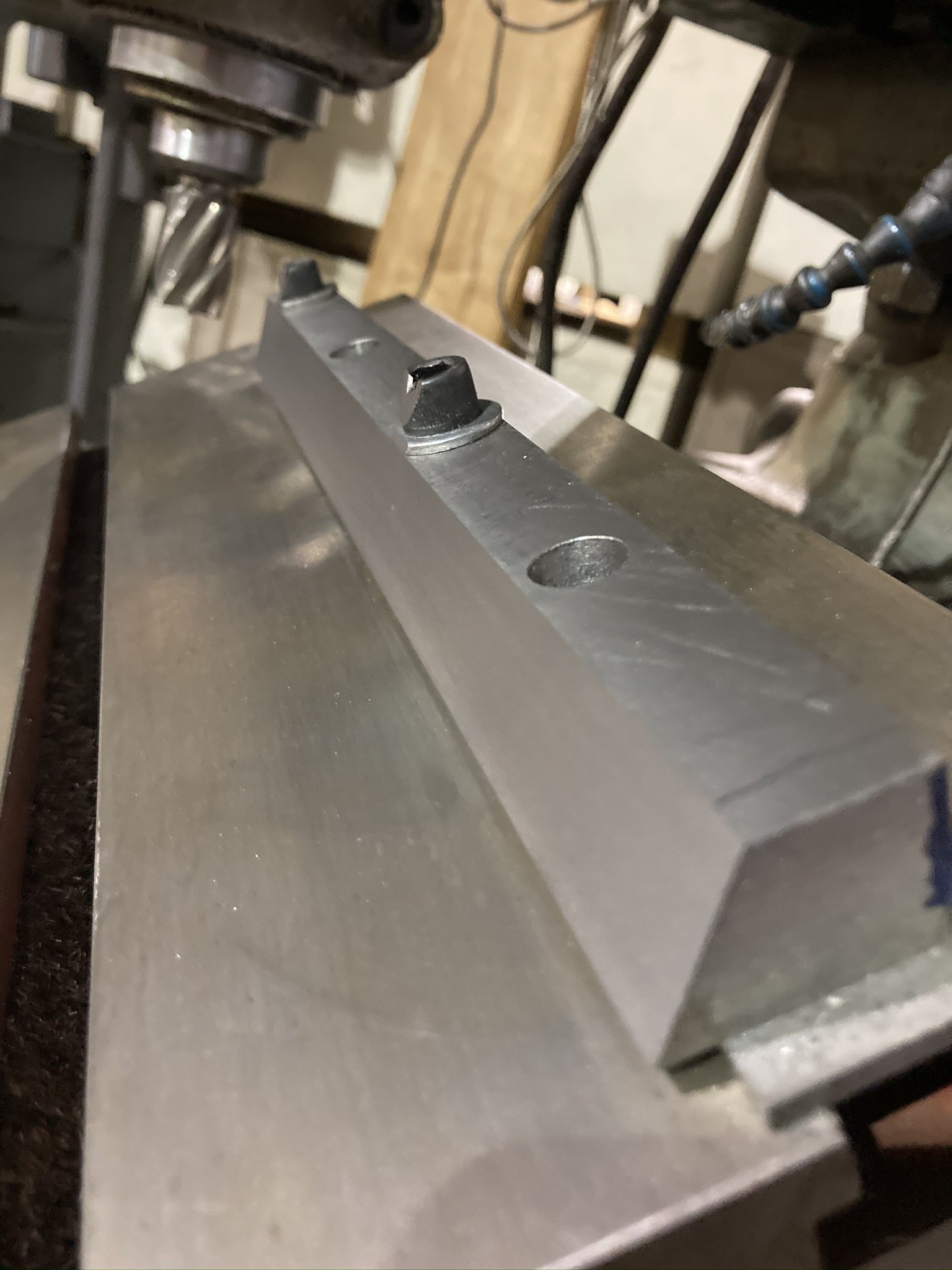

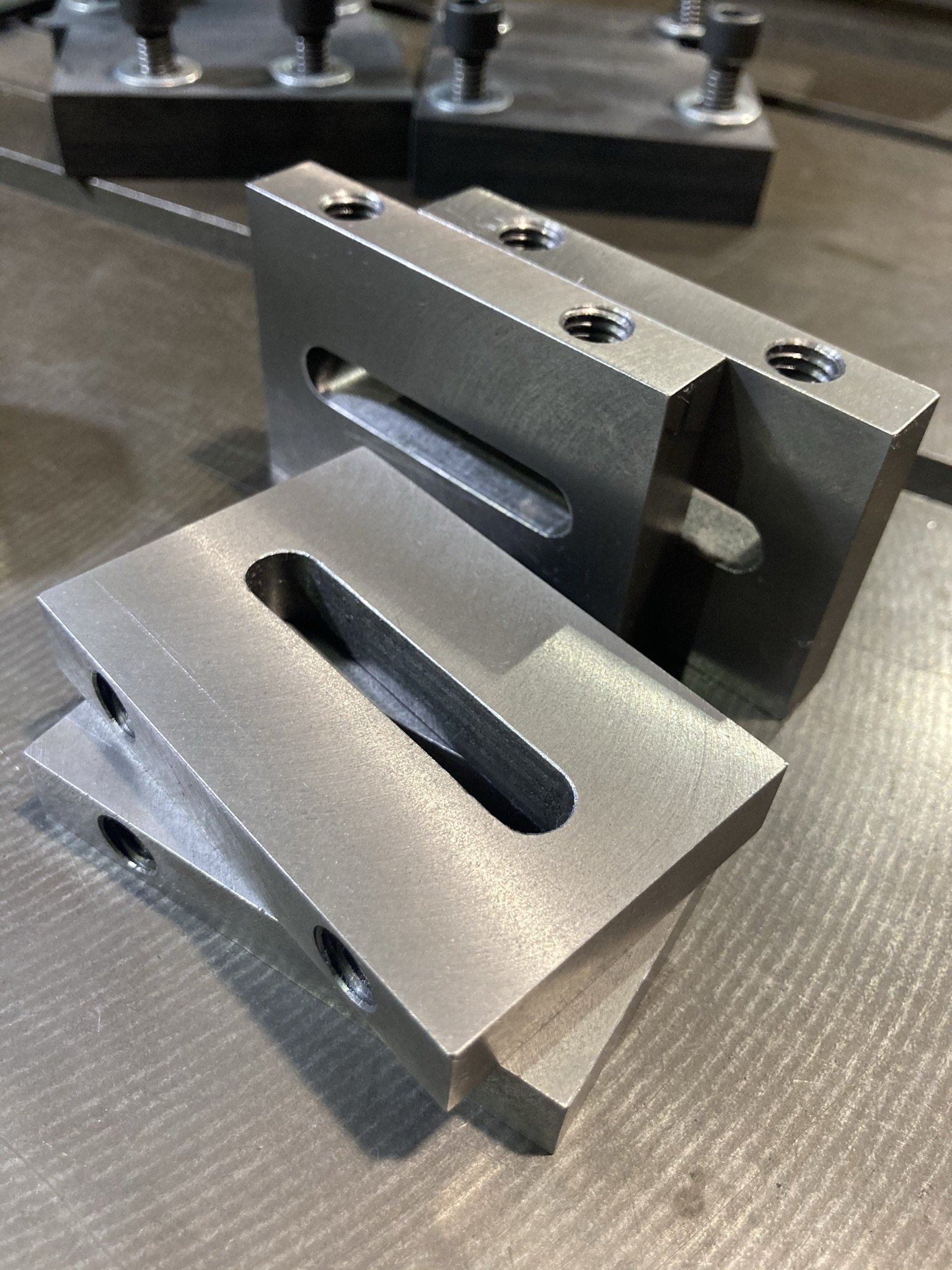

dresser pull hardware

This small run of parts was commissioned for holding latch-pulls on a custom-made dresser.

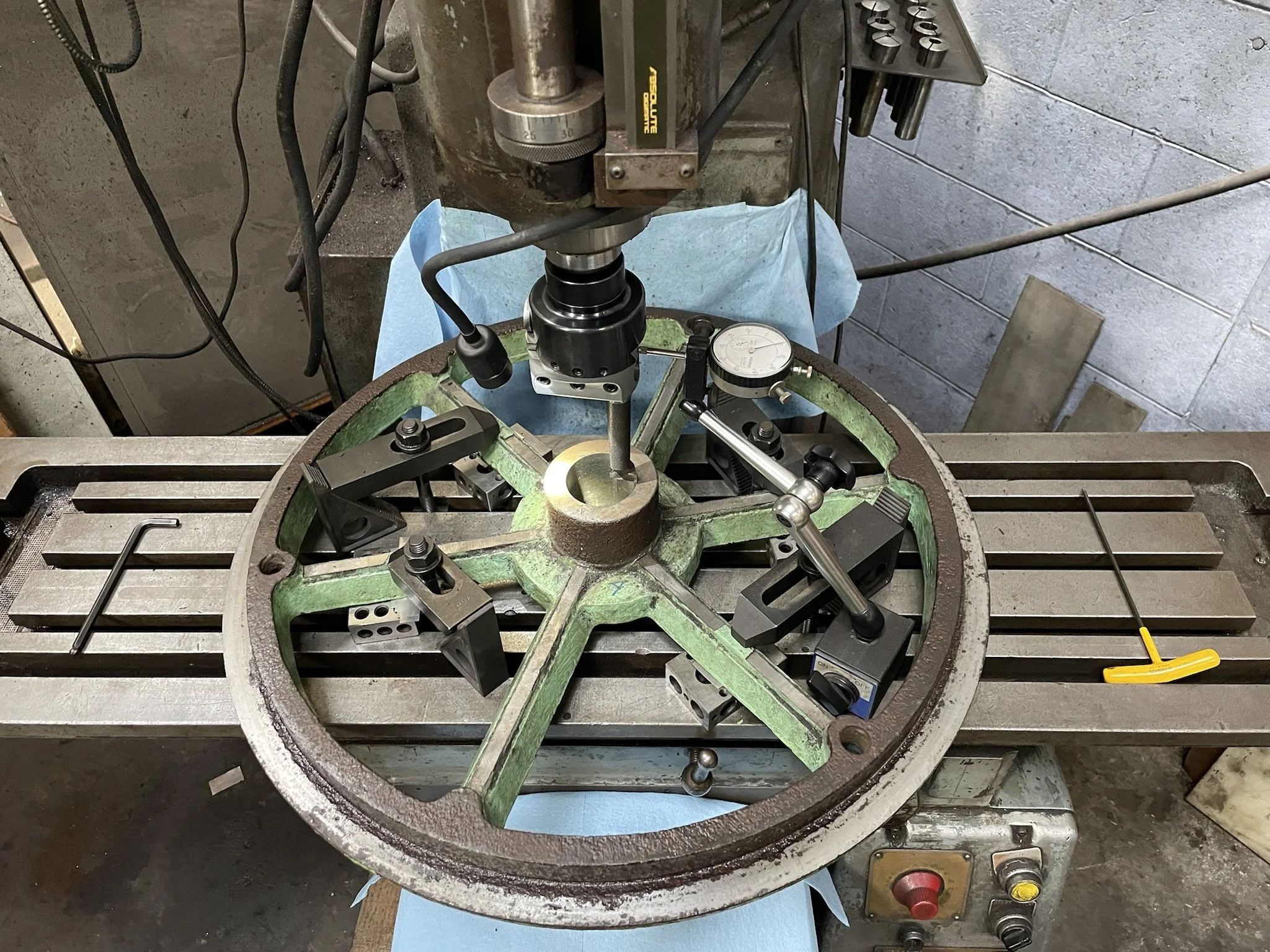

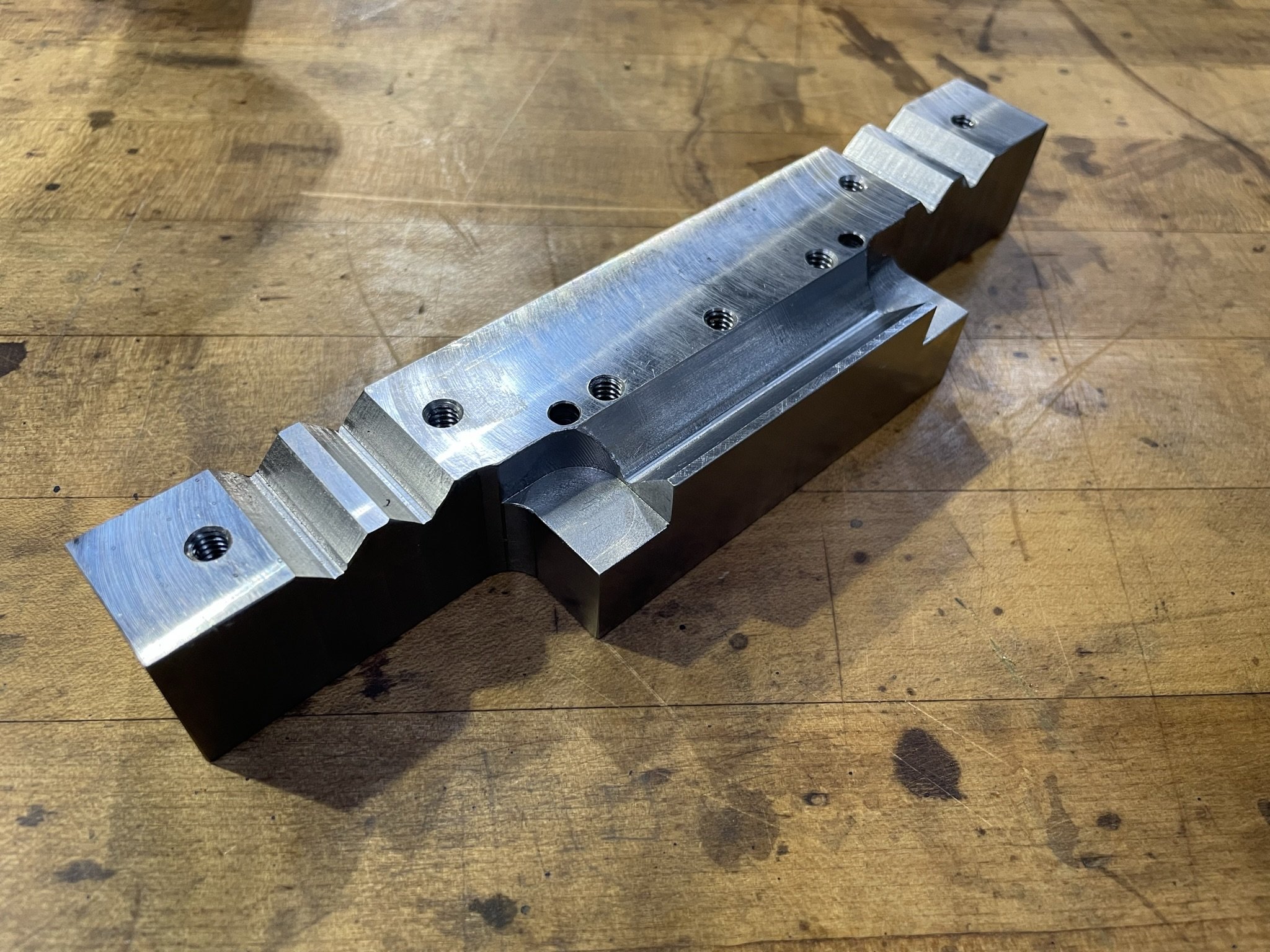

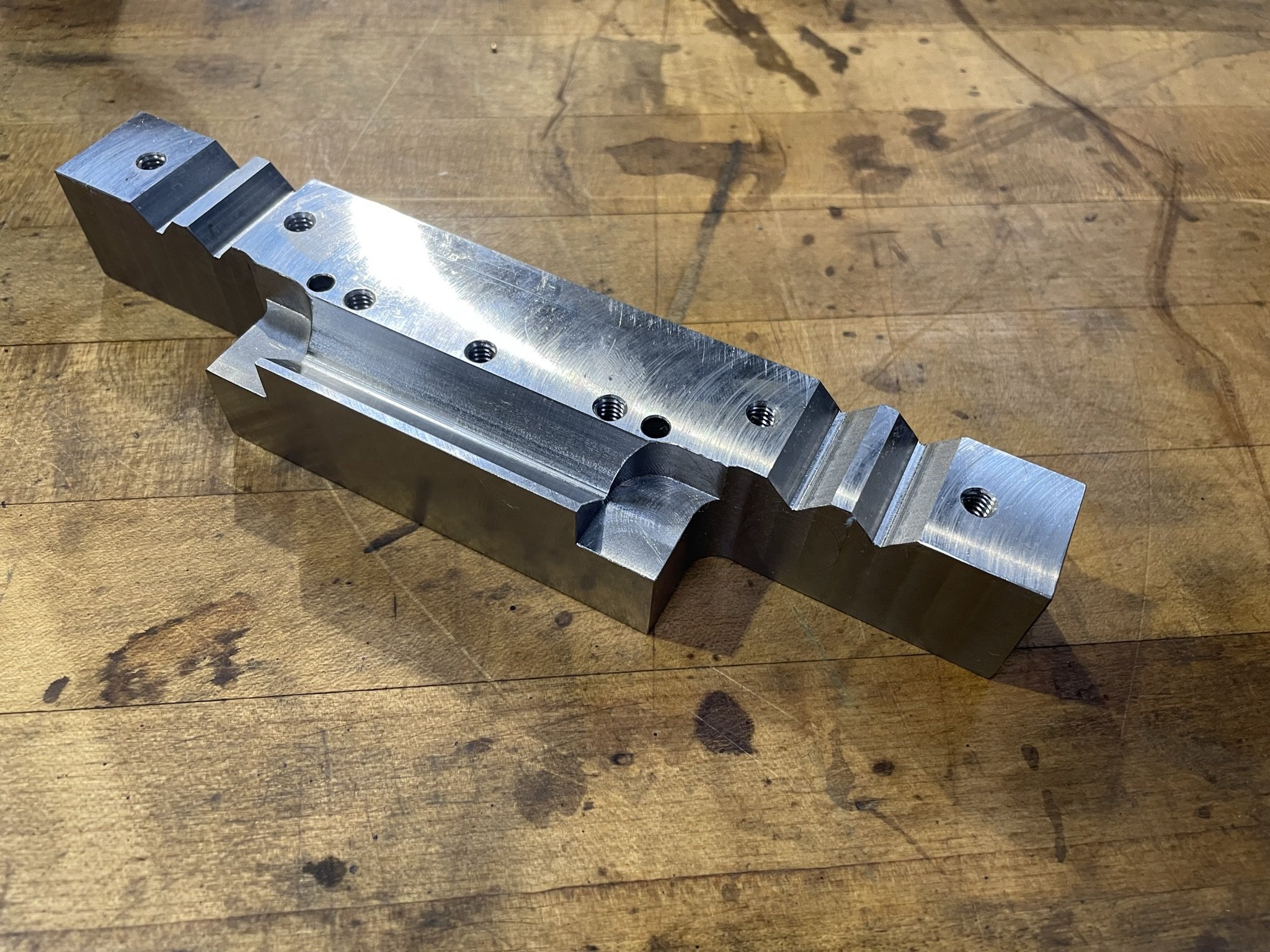

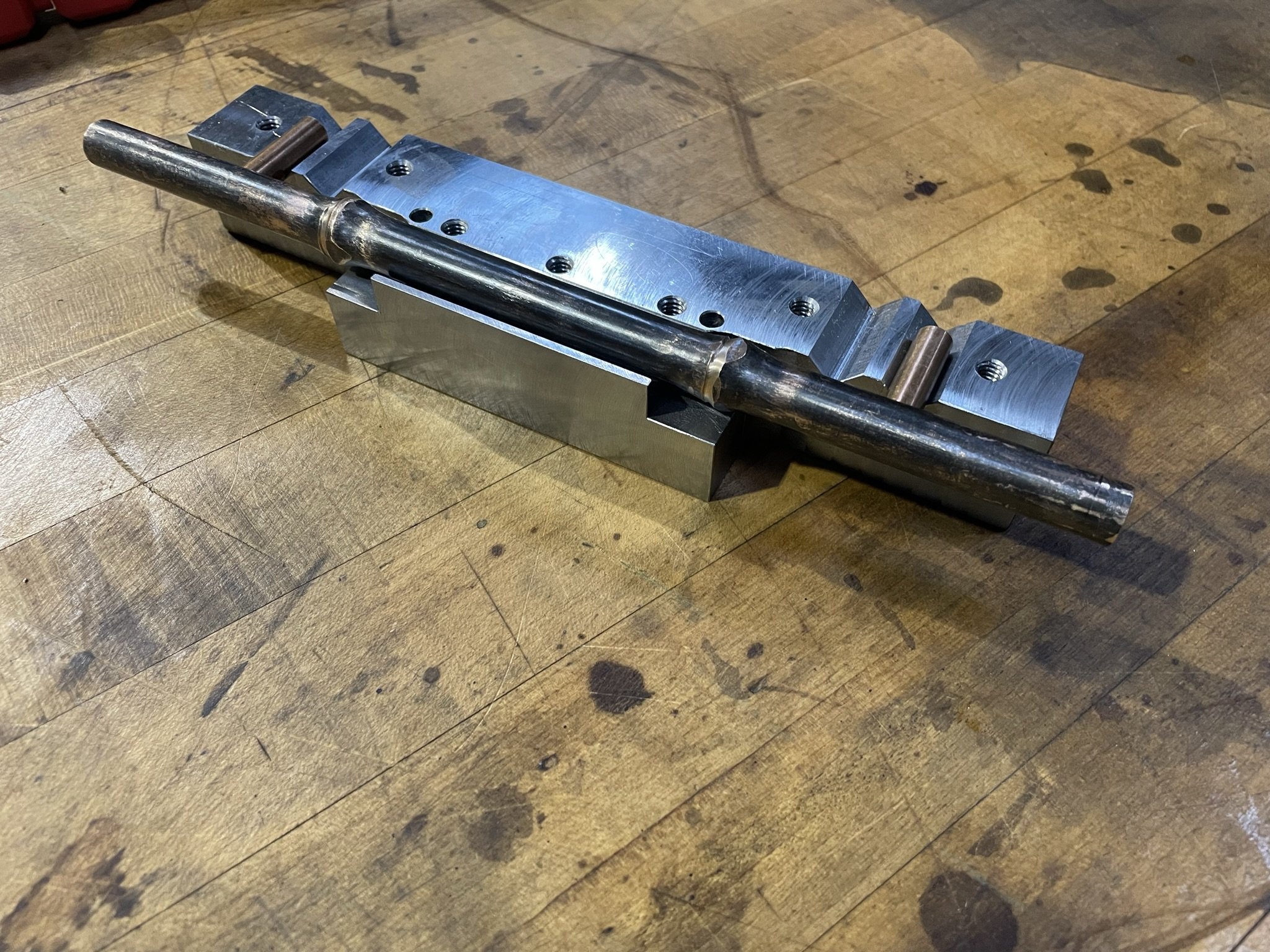

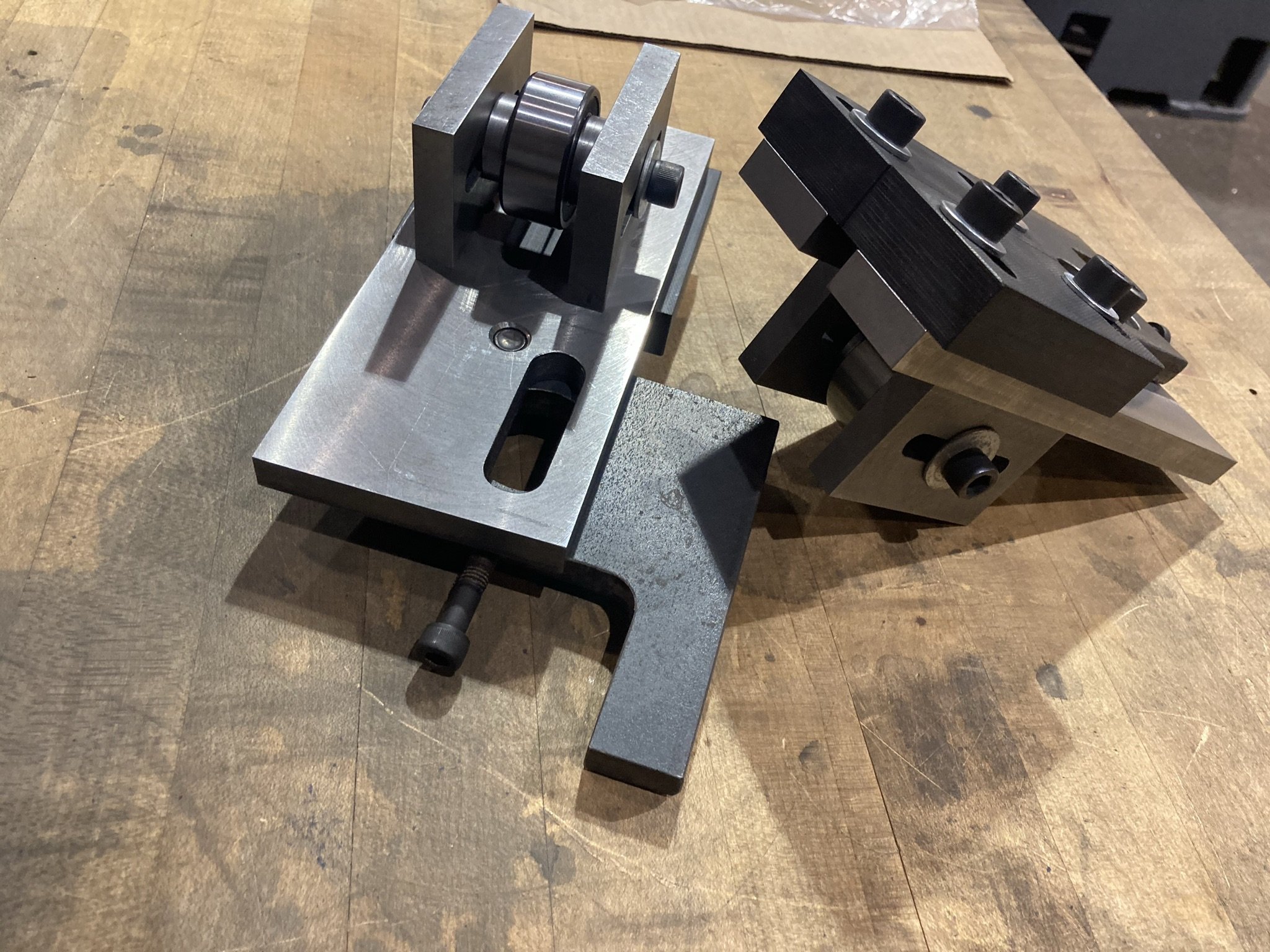

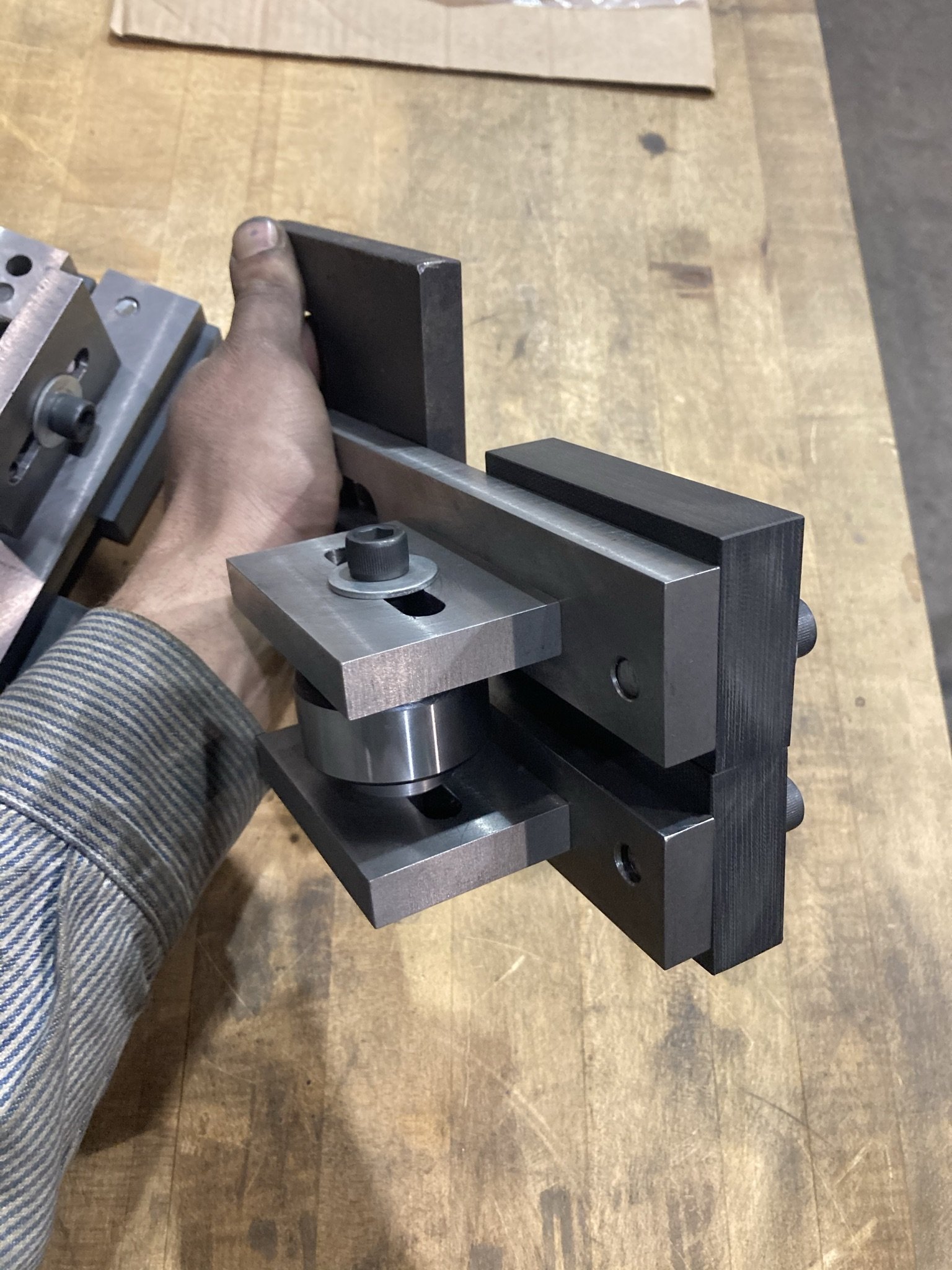

soldering jig

For the bronze cabinet pulls I also made this soldering jig to mate them with the standoffs. The deep V holds the pull and the shallower Vs hold the standoffs (for the two different sizes of pull) in position with threaded holes for clamping features.

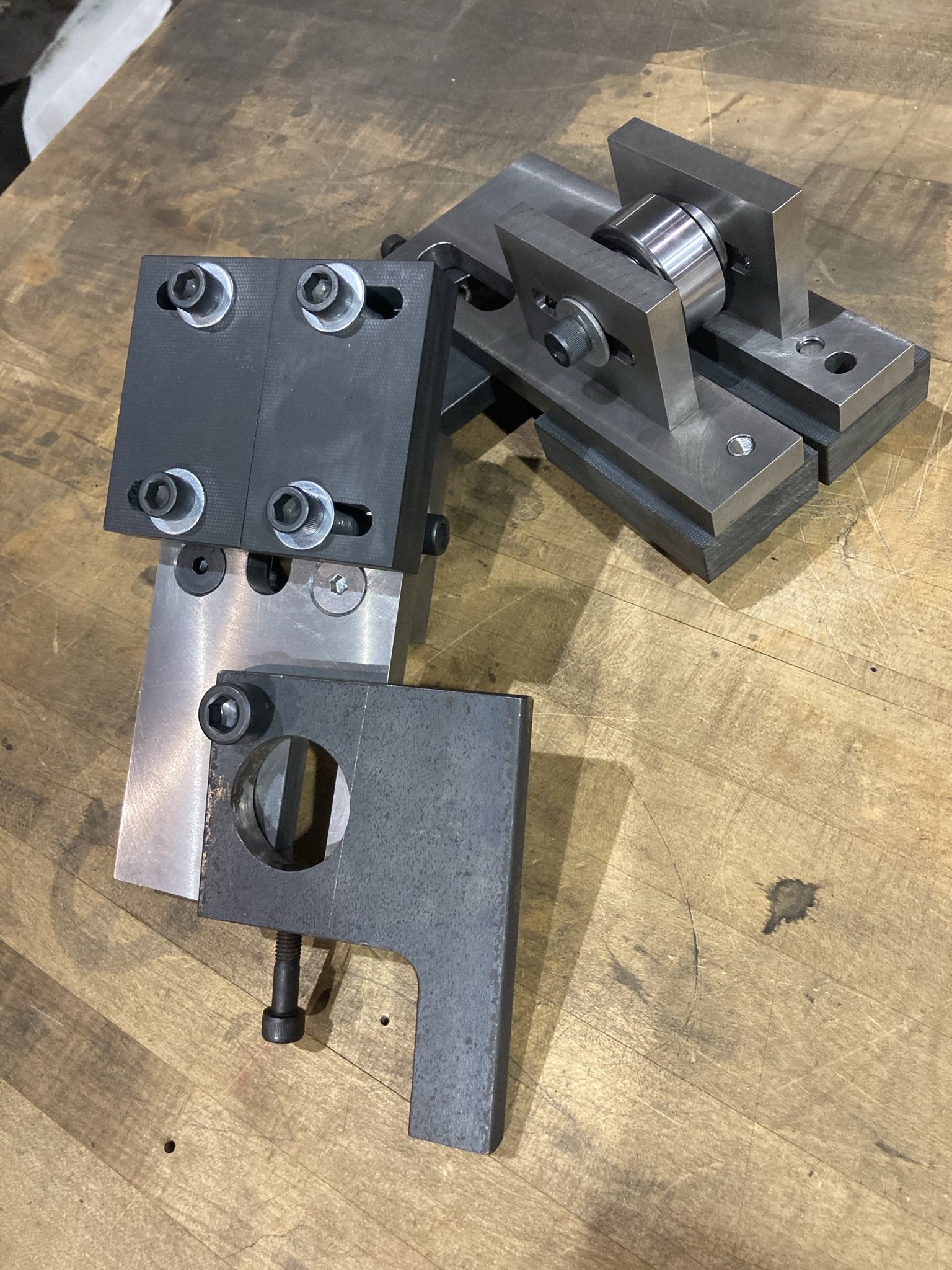

sawmill blade guides

These guides were another part of the band sawmill rebuild. They’re essentially precision brackets that hold a spinning bearing to support the back of the bandsaw blade which is adjustable forward and back, and low-friction garolite blocks to help with blade tracking, which can also be adjusted for wear.

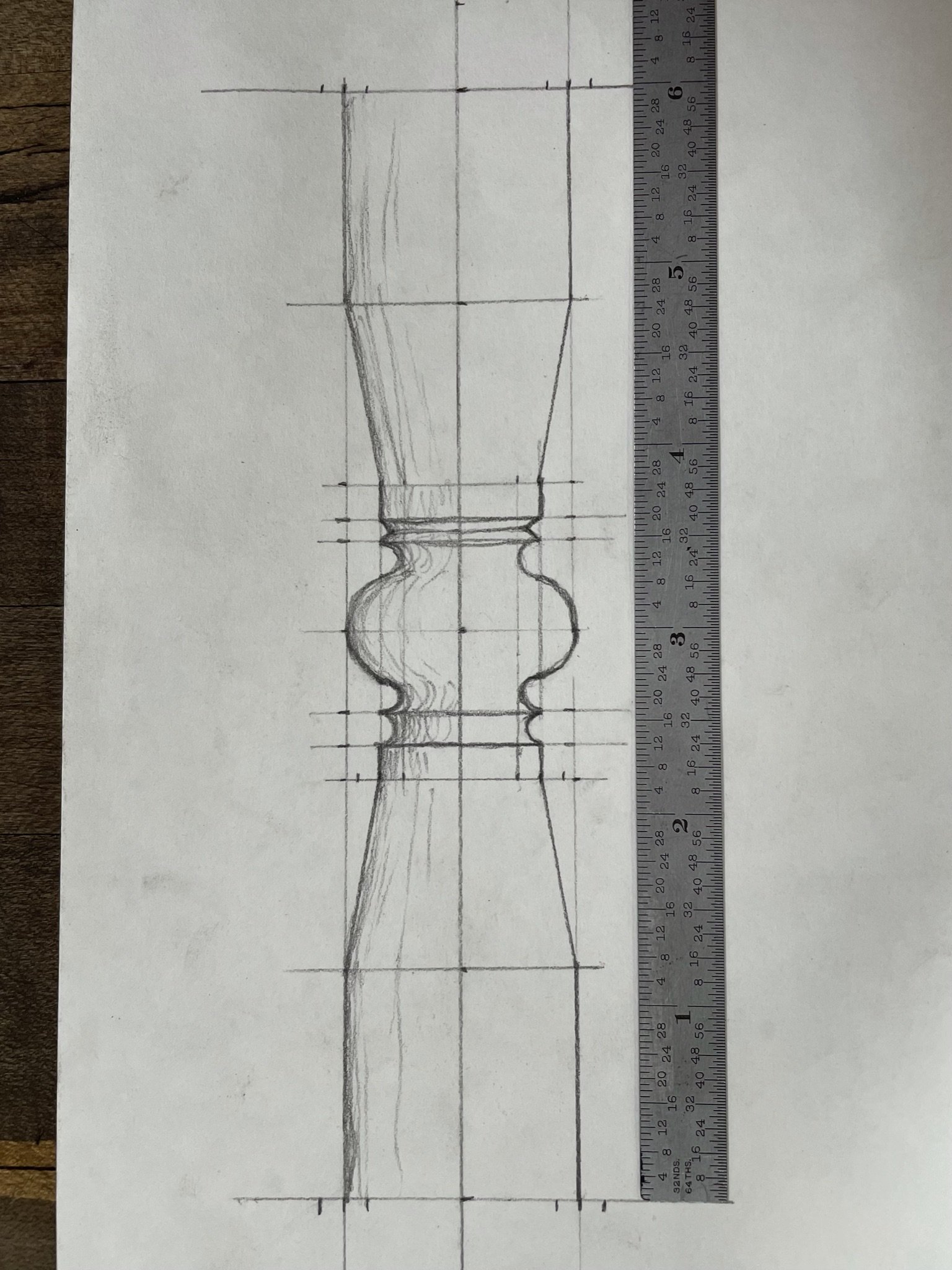

forging die pattern

This was a master pattern I made for another blacksmith who used it to make simple forging dies by pressing it between two hot blocks of steel, leaving the impression of this piece, which could then be used to forge more pieces into this shape. There was also a simpler version used to make a pre-forming die before using this one.

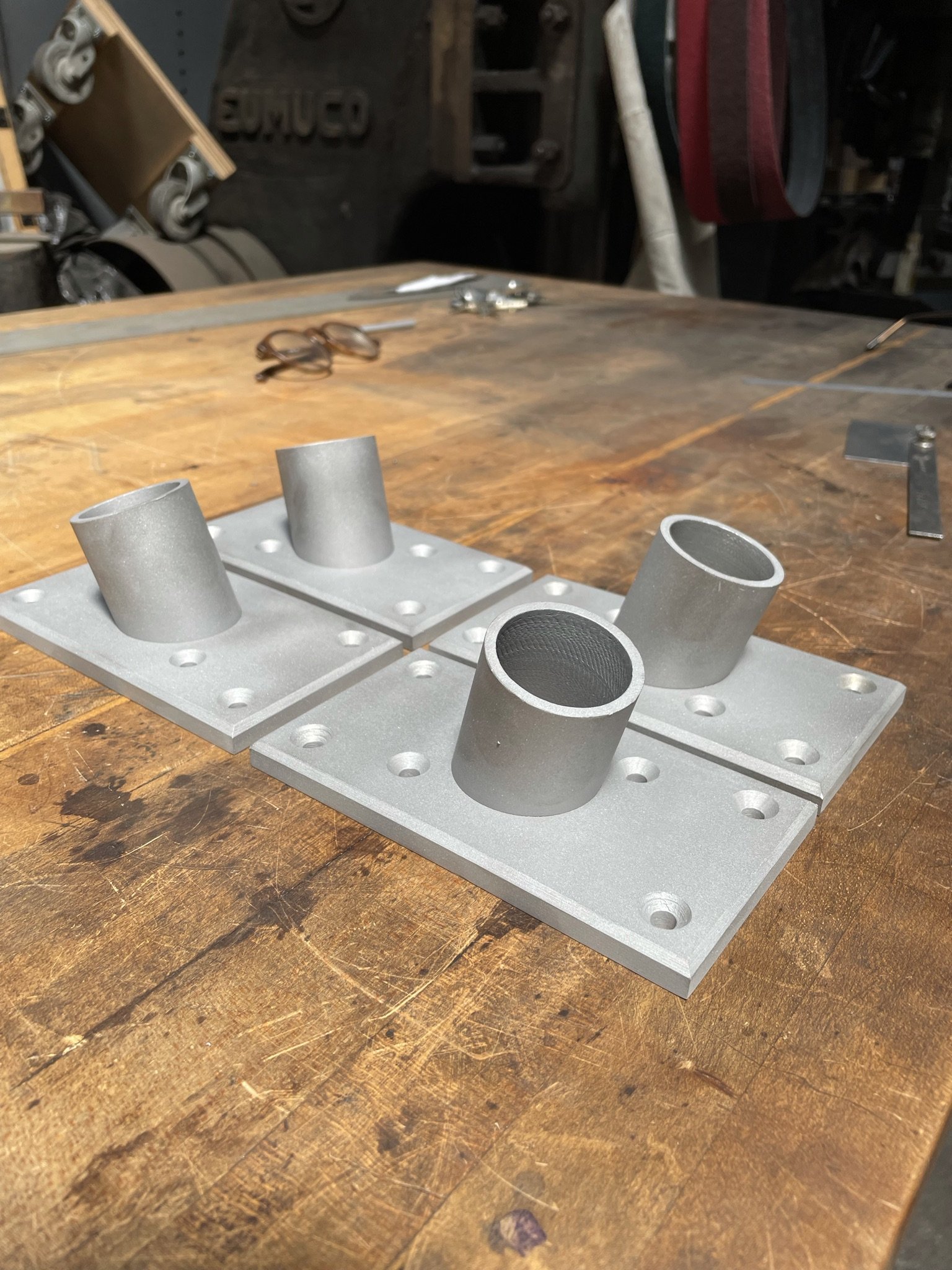

bench leg brackets

These brackets were made for a custom piece of furniture with these turned oak legs. I bored a compound hole into the base plates and welded in the appropriate size tubing to accept the tenons I turned on the legs.